Project

Our Project

Fusce tellus leo elementum in tortor id volutpat pellentesque ipsum luctus Curabitur laoree.

Additional New Soot Blower (10 Unit)

Location: Stesen Janakuasa Tuanku Muhriz

Date: 1/3/2022 (Outage unit 1)

Job details

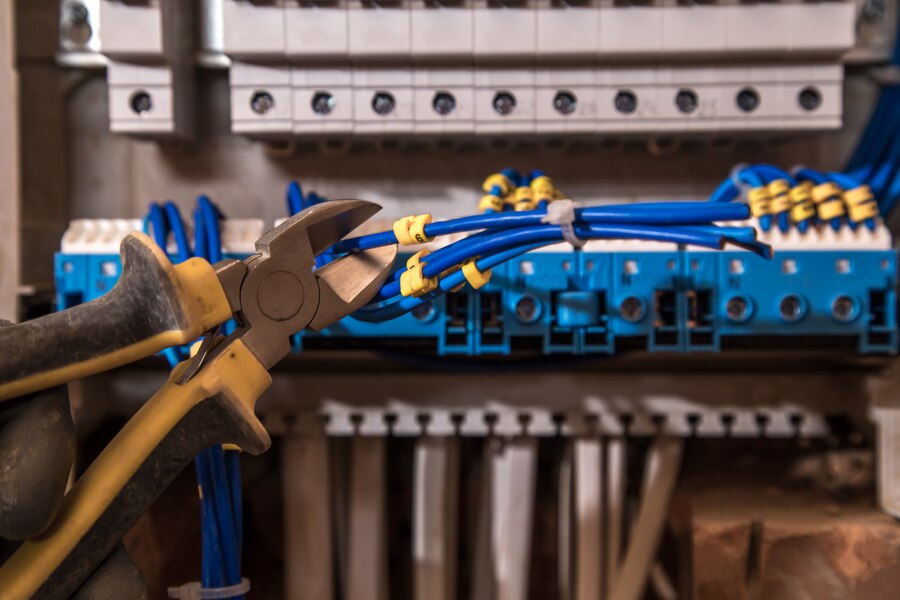

1. Installation of Cable Tray, Cable Support, Conduit for New Soot blower

2. Pulling new power cable and Earthing cable for Soot blower

3. Installation Soot Blower Contactor panel at Switchgear panel

4. Install new relay and Contactor

5. Install New I/O Panel

6. Motor Winding Resistance Test

7. Relocate Lighting and Termination

8. Manpower Supply to IPSM for Commissioning

9. Continuity Test for All Control Cable

10. Relocation Break Glass for Fire Fighting and Phone Boiler

11. Installation of Grouting for Panel

12. Download New PLC Programming

13. Function test for Limit Switch and Panel button for all new soot blower

14. Stroke Test and Rotation Check

15. Hot Commissioning for All New Soot blower

16. Fire Stop Penetration

Relocation Soot Blower (2 UNIT)

Location: Stesen Janakuasa Tuanku Muhriz

Date: .4/5/2022 (Outage unit 1)

Job details

1. Relocation 2unit Soot blower

2. Installation of Cable Tray, Cable Support, Conduit for 2 unit

3. Pulling new Cable and termination

4. Continuity Test for All Control Cable

5. Stroke Test and Rotation Check

6. Hot Commissioning for All New Soot blower

Mill Lube Oil Pump Motor Dismantle and Service

Location: Stesen Janakuasa Tuanku Muhriz

Date: 30/3/2022 (Outage Unit 1)

Job details

1. Complete laser Alignment with satisfactory result and document

2. Visual inspection and Painting

3. Modification work for install Jack bolt for alignment motor base

4. To perform pump alignment and motor modification work on motor base

Additional New Soot Blower

(10 Unit)

Location: Stesen Janakuasa Tuanku Muhriz

Date: 30/5/2022 (Outage Unit 2)

Job details

1. Installation of Cable Tray, Cable Support, Conduit for New Soot blower

2. Pulling new power cable and Earthing cable for Soot blower

3. Installation Soot Blower Contactor panel at Switchgear panel

4. Install new relay and Contactor

5. Install New I/O Panel

6. Motor Winding Resistance Test

7. Relocate Lighting and Termination

8. Manpower Supply to IPSM for Commissioning

9. Continuity Test for All Control Cable

10. Relocation Break Glass for Fire Fighting and Phone Boiler

11. Installation of Grouting for Panel

12. Download New PLC Programming

13. Function test for Limit Switch and Panel button for all new soot blower

14. Stroke Test and Rotation Check

15. Hot Commissioning for All New Soot blower

16. Fire Stop Penetration

Relocation Soot Blower

(2 Unit)

Location: Stesen Janakuasa Tuanku Muhriz

Date: (Outage Unit 2)

Job details

1. Relocation 2unit Soot blower

2. Installation of Cable Tray, Cable Support, Conduit for 2 unit

3. Pulling new Cable and termination

4. Continuity Test for All Control Cable

5. Stroke Test and Rotation Check

6. Hot Commissioning for All New Soot blower

Mill Lube Oil Pump Motor Dismantle and Service and Alignment Pump and Motor

Location: Stesen Janakuasa Tuanku Muhriz

Date: 25/6/2022 (Outage Unit 2)

Job details

1. Complete laser Alignment with satisfactory result and document

2. Visual inspection and Painting

3. Modification work for install Jack bolt for alignment motor base

4. To perform pump alignment and motor modification work on motor base

Paddle Mixer

Unit 1

Location: Stesen Janakuasa Tuanku Muhriz

Date: 15/10/2022

Job details

1. Installation Cable Tray, Cable Support, Conduit for Dust Loader

2. Cable Pulling for Main Panel to I/O Panel

3. Marshalling and Instrument Termination

4. Earthing Cable for Cable Tray

5. Control Valve Calibration

6. Motor Winding Resistance Test

7. Install new Sub DB panel and termination

8. Supply Manpower to IPSM for Commissioning

9. Fire Stop Penetration

10. Testing and Hot /Cold Commissioning

Paddle Mixer

Unit 2

Location: Stesen Janakuasa Tuanku Muhriz

Date: 15/12/2022

Job details

1. Installation Cable Tray, Cable Support, Conduit for Dust Loader

2. Cable Pulling for Main Panel to I/O Panel

3. Marshalling and Instrument Termination

4. Earthing Cable for Cable Tray

5. Control Valve Calibration

6. Motor Winding Resistance Test

7. Install new Sub DB panel and termination

8. Supply Manpower to IPSM for Commissioning

9. Fire Stop Penetration

10. Testing and Hot /Cold Commissioning

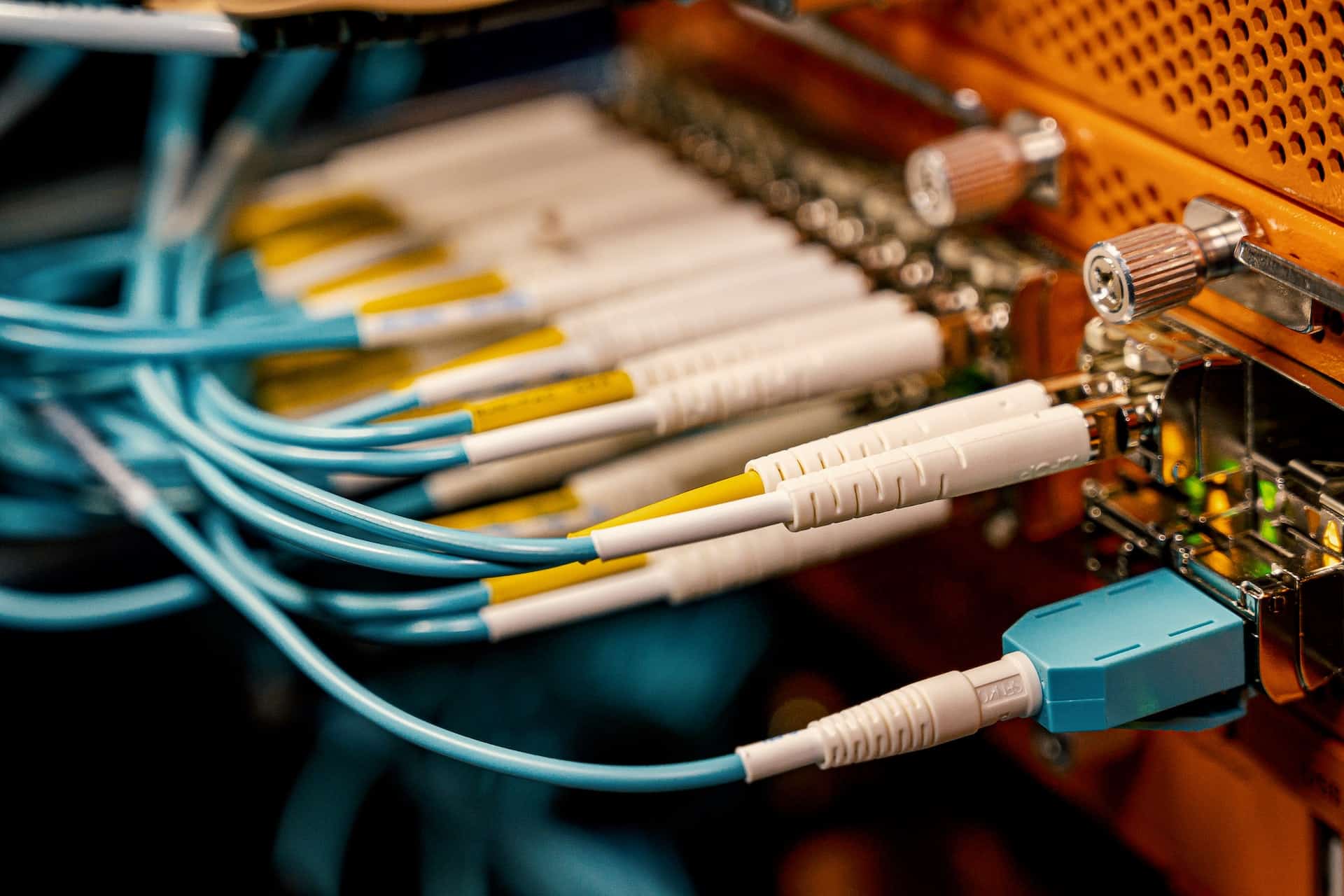

Fibre Optic Testing and

Troubleshooting

Location: Stesen Janakuasa Tuanku Muhriz

Date: 9/12/2022

Job details

1. OTDR Testing

Fibre Optic Installation, Splicing. Testing and

Troubleshooting

Location: All Perak

Date: 2021 until Now

Job details

1. Cable Pulling and Splicing, Fibre Jointing

2. Install Pole and Conduit

3. Testing and Troubleshooting

Electrical Troubleshooting for Genset, Dvor and Transformer Stabiliser

Location: KLIA

Date: 5/2/2022

Job details

1. Calibrate the voltage and current meter

2. To do the cleaning and clear the dust inside Automatic Voltage Regulator and

continuity check wiring inside the panel

Replacement for Dvor and Transformer Stabiliser Card 3 Phase and Genset AVR Card

Location: KLIA

Date: 8/7/2022

Job details

1. Troubleshoot 415v Genset low voltage and identify the problem part (Check

the AVR)

2. Calibrate the voltage and current meter

3. To do the cleaning and clear the dust inside Automatic Voltage Regulator and

continuity check wiring inside the panel

4. Replacement for AVR Electronic card for RYB Phase

5. Supply 2 Variable Resistor for Genset

Relay protection calibration and meter calibration at DVOR Transformer Stabiliser

Location: KLIA

Date: 8/9/2022

Job details

1. Calibrate the voltage and current meter

2. To do the cleaning and clear the dust inside Automatic Voltage Regulator and

continuity check wiring inside the panel

Replace Lighting

Billboard

Location: KLIA

Date: 29/2/2023

Job details

1. Replace all floodlight and Termination

2. Panel cleaning and termination

3. Testing

Replacement Sewage Pipeline from CCR Building to Mill C Unit 1 Sewage Pipe Riser

Location: JIMAH, Port Dickson, NS

Date: 4/9/2023

Job details

1. Dismantle Sewage Pipeline from CCR Building to Mill C Unit 1 Sewage Pipe

Riser

2. Installed temporary hose from CCR Building to Mill C Unit 1 Sewage Pipe Riser

3. Installed Sewage Pipeline from CCR Building to Mill C Unit 1 Sewage Pipe Riser

4. Final Inspection and Leak Test with Client.

Grouting Rectification at Fire Fighting Pump No 1 and 2

Location: JIMAH, Port Dickson, NS

Date: 18/8/2023

Job details

1. Hacking existing grouting at Fire Fighting Pump No 1 and 2

2. Checked levelling for Fire Fighting Pump No 1 and 2

3. Make New Grouting for Fire Fighting Pump No 1 and 2

4. Touch up and skim for New Grouting for Fire Fighting Pump No 1 and 2

5. Final Inspection with Client

Earthing Copper Installation at New Plant at BASF Petronas Gebeng

Location: Gebeng, Pahang

Date: 2/8/2023

Job details

1. Installed Earthing Copper Strip

2. Installed Earthing Chamber Concrete

3. Installed Earthing Rod with Joint and Clamp

4. Earth Resistance Test

5. Final Inspection with Client

Preventive & Corrective Maintenance for ALL Roller Shutter at Pangkalan Udara Sendayan

Location: Sendayan, NS

Date: 29/9/2023

Job details

1. Removed existing grease and dust at Roller Sutter rail

2. Repaired and Welding at side support for Roller Shutter

3. Applied New Grease for all Roller Shutter

4. Function Test for all Roller Shutter

5. Final Inspection with Client

Upgrade facility for Wisma Ahli Udara Building at Pangkalan Udara Sendayan

Location: Sendayan, NS

Date: 28/11/2023

Job details

1. Installed New Plaster Ceiling at Wisma Ahli Udara

2. Applied New Painting at Wisma Ahli Udara

3. Installed New Main Door at Wisma Ahli Udara

4. Installed Acrylic Board at Wisma Ahli Udara

5. Supply New Furniture at Wisma Ahli Udara

6. Final Inspection with Client

Install New Water Pipeline for Paddle

Mixer

Location: Stesen Janakuasa Tuanku Muhriz

Date: 16/5/2023

Job details

1. Installation New Water Pipeline from new tapping at Pipe rack

2. Welding every joint for pipe line

3. DPT Test for Welding point with Client.

4. Leak test for New Water Pipe line

5. Touch Up Paint for all New Pipeline

6. Final Inspection with Client

Grid Code Tester for 50MW LSS

Location: BIDOR, PERAK

Date: 12/1/2024

Job details

1. Grid Code Testing & Coordinator with GSO

• EMS GCT FD, APG and AHVC Test

• Quality of Service with CVD Installation

• Hot Commissioning (Internal GCT Test between tester and client)

• Anti Islanding Test

• Restart and Delivery of Energy to Grid system.

• Ramp Rate

• Grid Frequency Variation

• Reactive Power Capability

• Grid Voltage Variation

• Simulation Model Validation

• Fault Detection and Clearing Time Limit

• Establish Capacity Test

• Fault Ride Through

• EMS Online

Grid Code Tester for 50MW LSS

Location: Sandakan, Sabah

Date: 15/11/2023

Job details

1. Grid Code Testing & Coordinator with GSO/SESB

• Power Quality of Service

• Hot Commissioning (Internal GCT Test between tester and client)

• Anti Islanding Test

• Restart and Delivery of Energy to Grid system.

• Ramp Rate

• Grid Frequency Variation

• Reactive Power Capability

• Grid Voltage Variation

• Fault Detection and Clearing Time Limit

Career

Explore your Future

We give you the tools you need to discover your perfect job match, and the freedom and support to take your career to the next level.

No Daftar:202001035033 (1391354-M)

Igniting innovation, one pulse at a time. Engineering the future with precision and passion. Where technology meets power, possibilities are limitless.”